In this article

Expanding the food safe menu with SKF

To meet the increasing demand for hygienic design in all food processing assets, SKF has added another innovative product to its range: a standard Deep Groove Ball Bearing in a food safe configuration.

A SKF customer survey revealed that no fewer than 87% of respondents involved in food production and food manufacturing equipment felt this type of product was important or very important for their assets.

The result is the new SKF Foodline Deep Groove Ball Bearing, designed with the principal objective of reducing food safety risks.

The SKF Foodline ball bearings have sealing technology that minimises the risk of grease escaping the bearing. If leakage does occur, the NSF H1 registered, religion-compliant and allergen-free grease is permitted for incidental food contact. As an additional precaution, the blue material used for the seal – made from FDA and EC approved food grade nitrile rubber compounds – makes it easy to identify fragments in the food stream.

But that’s not all that makes the new bearing an ideal choice for the sector. It also combines several other proven SKF technologies.

SKF Explorer performance class bearings

Made from extremely clean, highly homogeneous steel, using a unique heat treatment process, SKF Explorer bearings offer maximized rating life, higher running accuracy than ISO standard, and exceptional strength and durability.

High-efficiency food grade seal

SKF RSH seal technology ensures excellent water and solid contaminant exclusion. It also complies with US Food and Drug Administration (FDA) and European Community (EC) recommendations.

High-performance food grade grease

A specially developed grease – proven effective even in cases of incidental water or detergent penetration. Registered by NSF as category H1, and allergen-free, it meets all allergen standards issued by the European Community (EC)

Halal and Kosher certified Further lubricant options include food grade Solid Oil, and alternative grease fills to your specific requirements.

One of the family

The new SKF Foodline Deep Groove Ball Bearing is the latest option in the SKF Deep Groove family.

The whole range, outlined opposite,, complies with industry standards, and uses food grade grease and optically detectable food grade sealing.

*Solid Oil: Food grade Solid Oil – ideal when extended life is required, or in harsh environments – is a polymer matrix, saturated with a lubrication oil that completely fills the internal space in a bearing, and encapsulates the cage and rolling elements. It contains 2-4 times more lubricating oil than a corresponding sealed, grease-filled bearing.

Lubricated for life – and food safety

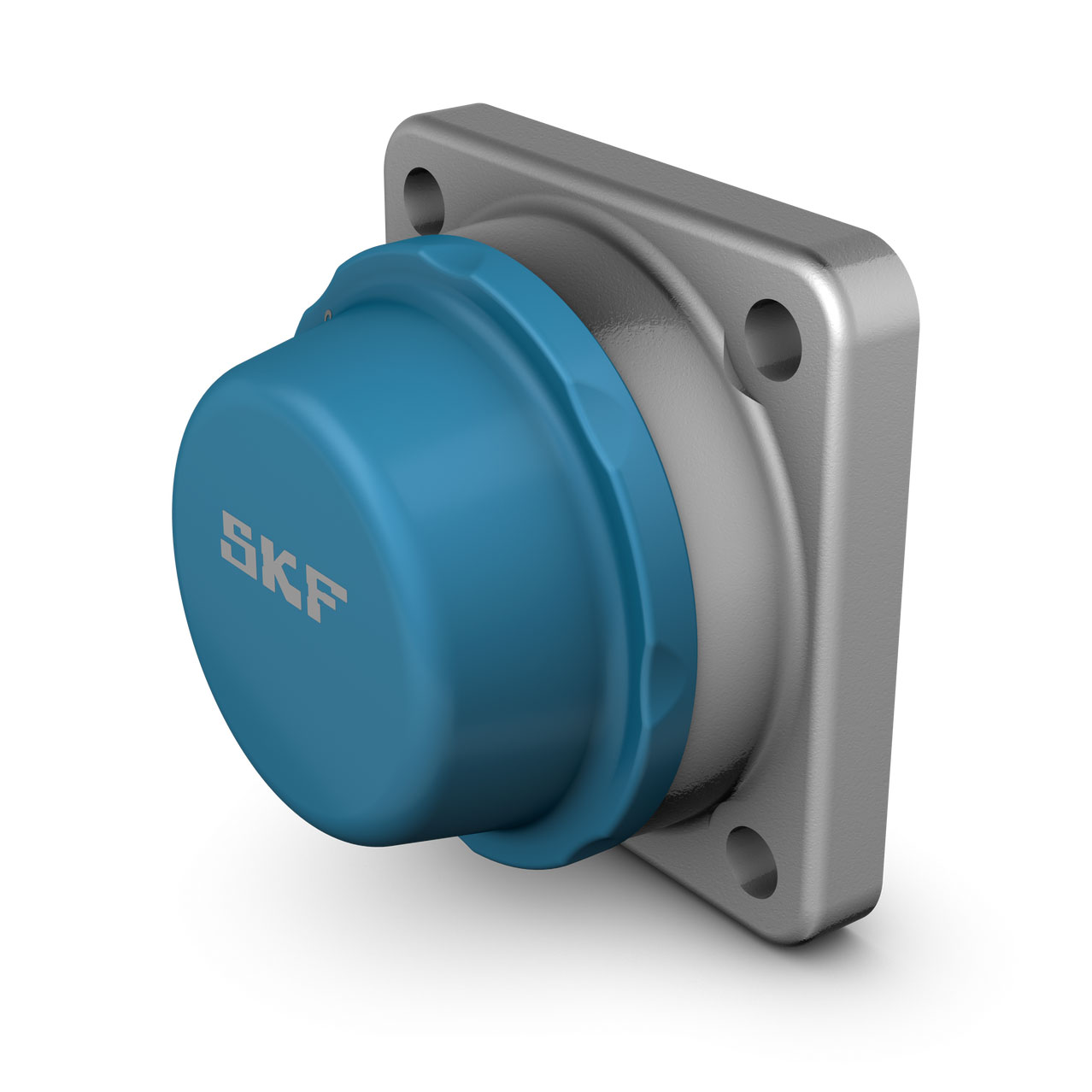

Alongside the new food safe Deep Groove Ball Bearing, SKF Foodline Ball Bearing Insert Units – originally introduced over 10 years ago – have been updated and improved to meet the sector’s changing food hygiene requirements.

Now they not only meet hygienic design standards, but are also sealed to prevent ingress of penetrative, caustic-based disinfecting fluids. All components meet food and beverage industry regulatory requirements.

To further improve reliability, they contain an NSF H1 registered grease specially formulated for optimum performance in the presence of caustic fluids.

The Blue Range of SKF Foodline ball bearing units offers a comprehensive selection of hygienic and high-performance bearing unit solutions, for the most demanding food and beverage environments. Specially developed to help eliminate contaminants and to reduce the spread of bacteria, they are lubricated for life and designed to withstand frequent washdowns.

Meanwhile, a new SKF general purpose food grade grease has just been launched.

Formulated to replace LGFP 2 in System 24 lubricators, LGFG 2 is a high-performance food grade grease, which uses complex calcium sulphonate thickener technology and a white mineral oil. Suitable for high loads, wet environments and fluctuating temperatures, it is ideal for food and beverage applications.

So when you’re looking for a full menu of lubricants and bearings to meet your requirements in the food and beverage sector, make sure you consider SKF for starters.

For more information on Bearing Solutions and to get in touch with one of our ERIKS Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#SKF #ERIKS #LetsMakeIndustryWorkBetter #Bearings #Innovation #RiskReduction #Solutions #Food