In this article

Making Online Monitoring part of your maintenance strategy

Part 1: Evolution, not revolution. It’s easy to promise a quick fix that reduces maintenance costs, increases uptime and efficiency, and optimises productivity. It’s much harder to make those things a reality. And anyway, in reality they’ll never be achieved with a quick fix. But using an iterative process, and with the right know-how, advice and support, making Online Monitoring part of your maintenance strategy can deliver those benefits worth waiting for.

A successful maintenance strategy usually comprises five distinct maintenance methodologies. Firstly, Reactive Maintenance. You could call this the “putting out fires” approach. Secondly, Preventive Maintenance.

As the name suggests, this is like taking steps to prevent fires, in preference to having to fight them. However it has its disadvantages, as it tends to be time-based. So if component X is due to be replaced after 12 months, but fails after 11 months, it’s replaced with a new one. Then this is itself replaced on the original 12-month anniversary “because the maintenance schedule says so”. As a maintenance solution, that’s far from cost-effective.

It’s also disruptive because it is unavoidably interventionist. When it’s time for a scheduled maintenance action such as cleaning or replacement of components, then production is halted and downtime accumulates.

The third methodology is Condition-based Maintenance. This is similar to the way cars are maintained. On a car, variables such as tyre pressures, oil temperature, fuel level etc. are individually monitored, then maintenance is carried out according to how and when they stray outside predetermined parameters.

It is significantly less disruptive than Preventive Maintenance, as intervention is only made when the condition of the assets demands it. Their condition can be established in a number of ways, including visual inspection, measurement, and trending analysis.

The fourth methodology is Predictive Maintenance. This is where Online Monitoring plays its part, and we’ll look at it in more detail in this and subsequent articles.

Lastly, outside the scope of these articles, is the fifth methodology: Prescriptive Maintenance.

A marathon, not a sprint

So how and when do you incorporate Predictive Maintenance into your maintenance strategy, and what role does Online Monitoring play?

Think about running a marathon. You wouldn’t leap off the couch and immediately start running 26.2 miles. So if you are thinking of adopting Predictive Maintenance, you shouldn’t expect to start Online Monitoring tomorrow.

The necessary timescale makes this a marathon, not a sprint. And to make it effective, you need to start from a mature Condition Based Maintenance methodology, which has already provided you with useful data about your assets.

It’s sometimes believed that Online Monitoring of one critical asset will transform maintenance, increase uptime and efficiency and optimise productivity. But just as a marathon runner’s fitness, health and equipment are all interrelated in achieving their goal, so are all the assets of industrial production.

You can’t fully prepare for a marathon simply by investing in new trainers. You can’t effectively apply the Predictive Maintenance methodology simply by monitoring one asset.

The more assets you monitor, the better. The more comprehensive the picture you will paint, and the more accurately you will be able to predict the scale and timing of maintenance requirements.

Knowledge in, understanding out

For a car, Predictive Maintenance would involve monitoring of several variables – such as oil pressure and temperature, miles per gallon and so on – then combining the data in a calculation resulting in a predictive outcome: how many miles of driving you have left before the car needs refuelling.

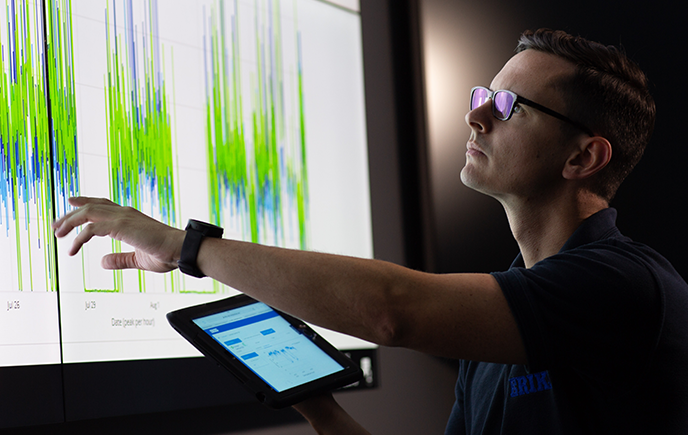

In the same way in an industrial setting, Predictive Maintenance involves Online Monitoring of multiple variables such as vibration, temperature, and oil pressure. It has the significant advantage over other methods, of being non-intrusive and non-disruptive, as well as providing larger quantities of data. This can be used in a predictive calculation to inform maintenance scheduling. It can also be compared with historical and process data to identify trends, which may help with re-engineering assets or rethinking processes, for greater efficiency and productivity.

By Online Monitoring as many assets as possible, and assessing the results against a sizeable historical database, you can:

- gain a full understanding of your processes and operations

- identify key factors such as:

- how operations are affecting components’ Mean Time Between Failure

- how soon you need to make a maintenance intervention to

- reduce downtime, optimise efficiency, or even avoid a catastrophic failure.

Achieving Predictive Maintenance through Online Monitoring has to be an evolution. But the results can be revolutionary.

For more information about Online Monitoring, contact your local ERIKS Service Centre, who will be happy to discuss your Assesst Managment options with you.

#ERIKS #LetsMakeIndustryWorkBetter #OnlineMonitoring #Maintenance #Strategy