The Hidden Cost of 'Cheaper' Engineering Components

When every pound counts, the temptation to cut corners grows. But in engineering, the cheapest optio...

Our extensive knowledge of fluid power engineering, transfer and control solutions combined with our multi-brand approach ensures that the solutions we specify and deploy will deliver optimum results for what are normally mission critical applications. And we'll do it on time, to budget and support it throughout its life.

This approach, together with the wide and deep technical experience of our regional application engineers allow us to offer a truly comprehensive, national service that's built around an expertly managed robust and flexible supply chain that thousands of customers rely on every day.

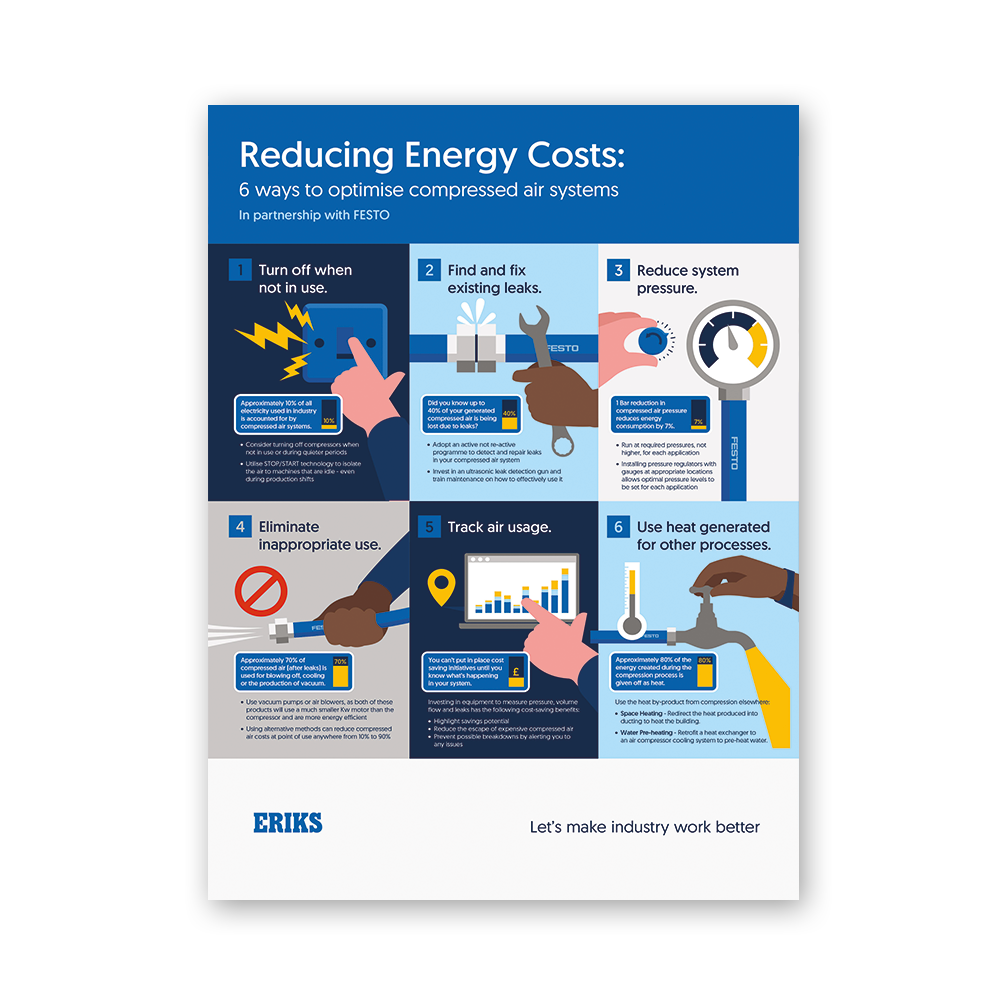

Here are 6x things that you can do now to optimize your Compressed Air System and reduce energy costs!

Supplying products for your fluid power needs is the easy part.

Knowing the most cost-effective and efficient products, the most appropriate solutions and the most sustainable choices is harder.

Knowing how to reduce your Total Cost of Ownership and optimise your productivity is harder still. Knowing how to service, support and maintain products – from purchase to end of service life – is even harder.

But ERIKS’ experience and expertise help to make it look easy. Our breadth and depth of partner brands enables us to meet all your fluid power needs, always.

Find out more about ERIKS Fluid Power Capability in the new brochure.

50% of people don't know the lead times on spares for their critical equipment. Obsolescence is becoming an ever-familiar term, and with so many companies still adopting the 'if it ain't broke, don't fix it' adage, it means we are dealing with some very old equipment, much of which is, or becoming obsolete.

In fact, our recent research suggested that 50% of equipment used in 65% of factories is over 10 years old.

HOW DO WE MITIGATE THE RISK?

Working in conjunction with Festo, we have identified and selected a range of high-quality products that are designed to meet the most common industry applications, particularly suited to the Food and Beverage, Pharmaceutical and Automotive Industries. Available to order at any time and ready for dispatch, the new core range contains more than 35,000 products.

The new home for ERIKS News, Blogs and Case Studies - keep up to date with all the latest news and updates in one place

The latest:

When every pound counts, the temptation to cut corners grows. But in engineering, the cheapest optio...

Saving you time and money, each and every day

Operating in a high production environment, a pet food manufacturer was experiencing costly issues during the phase-out of the valve manifolds on the filing line. But ERIKS were on hand to provide an upgraded solution that elimated the problems and drove down costs.

ERIKS OIL SAMPLING AND ANALYSIS

Poor maintenance, failing components and contaminated hose assemblies can all lead to oil contamination. Sampling and analysisng your hydraulic system oil can:

EXPERT ANALYSIS AND INTERPRETATION

Provide ERIKS with a sample of oil from any hydraulic system, and we submit it for independant laboratory analysis. Our experienced Application Engineers will then produce a detailed evaluation of the results including:

Across all industries leakage averages 30% of the total produced, with some sites losing as much as 60% of the total air generated.

These losses result in increased energy consumption and costs, counter-intuitive to businesses' CSR goals.

For all general enquiries use the Enquire Online form - we'll connect you with the best member of our team for your query. Alternatively, look up your local service centre...

We are proud to boast a strong team of technical specialists in each of our product and service areas. If you have a technical question a member of our team would be happy to help.

At ERIKS we strive to deliver the best quality service and products. As part of this goal we encourage customers to submit feedback on their experiences so we can resolve any issues and concerns.