In this article

Below the belt - Are your pulleys costing you?

Traditionally, the cure for an inefficient belt drive has been to simply replace the worn one with a new one. However, Gareth Lenton, ERIKS General Manager for Power Transmission, argues that the replacement of a pulley is a far more effective way to resolve your problems.

Looking beneath the surface

Remarkably, as many as 50% of new belts are actually fitted to worn pulleys. Pulleys are just as susceptible to wear and tear as they go through the rigours of everyday life, yet in so many cases, their condition is overlooked and passes right under the nose of the manager.

With that in mind, it must be stressed that determining a pulley’s condition is not a difficult task, nor does it require any expensive tools or machinery. A simple tool in the form of the Fenner Pulley Groove Gauge – which can fit onto any keyring – is enough to determine whether a pulley actually needs to be replaced.

Simple pulley inspection

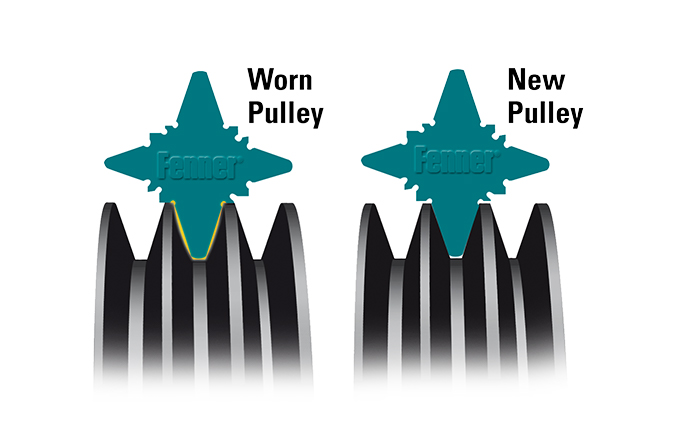

Simply clean off a section of the pulley and insert the appropriate width gauge profile into the groove, and if there’s more than 5% wear on the pulley’s pitch-line, then it needs to be replaced. Another good rule of thumb is that when the gauge is inserted, there should be no visible gaps at the sides.

You should also bear in mind, if there are any gaps or movement, this indicates that the belt isn’t sitting flush with the pulley and therefore it’s unable to produce the optimum amount of friction to operate the drive as efficiently as possible.

Improving drive efficiency

In reality, replacing a worn belt but ignoring pulley condition will do little to improve the efficiency of a drive, but it will reduce the life of the new belt. And, from a financial stand-point, poor drive efficiency will have a significant impact on both overall plant production and energy bills.

Prevention rather than cure

Although it’s inevitable that pulley damage will occur, correct installation remains key. Research has suggested that 70% of belt friction drives are actually incorrectly installed – which is quite an astounding figure.

Firstly, the maintenance manager must ensure that the most appropriate drive has been chosen. This will ensure the use of fewer belts and will reduce loading on machine bearings, increasing the systems lifespan and reducing potential downtime.

Once the correct drive has been selected, it must be installed effectively. Alignment is key and there are various ways to test this – From holding a taught piece of string across the pulley faces in different positions, to the most effective way, the Fenner laser alignment gauge.

By making use of the correct available tools, the drive is far more likely to deliver its maximum rated power, at its premium efficiency.

Auditing efficiency

In addition to correctly choosing and installing the most appropriate drive for your application, it’s advised that you conduct regular health inspections. These are neither difficult nor time-consuming. If you are looking to conduct these audits independently, I would recommend storing a full belt efficiency kit on site, such as the one from Fenner, which includes a belt tension indicator, a drive alignment laser and a pulley groove gauge.

Best practice maintenance for on-going efficiency

Given the frequency of belt drives in industrial applications, it’s vitally important that maintenance managers pay equal attention to the pulley and the belt, right through to installation and planned checks – only then will you truly reap the rewards of an optimised and highly efficient belt drive system.

Request your FREE pulley gauge today!

An essential item for your engineering toolbox, get yours today - no catch, we're just happy to help.

For more information on Power Transmissions or to get in touch with one of our ERIKS Power Transmission Specialists, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#ERIKS #LetsMakeIndustryWorkBetter #Fenner #Pulley #RepairReplace