In this article

Engineering the perfect drive solution

Common sense will tell you that ‘the perfect drive solution‘ can really save you money, and with more than 120 years of expertise in the field of drive belts, there’s no one better to assist their customers than Continental. From development of tailormade solutions, to design and maintenance services, Conti are the complete package.

2021 sees technology company, Continental, celebrate its 150th anniversary, a long- standing history that has seen them have a decisive influence on drive belts, resulting in true technological progress – beginning with the simple V-belt in 1889.

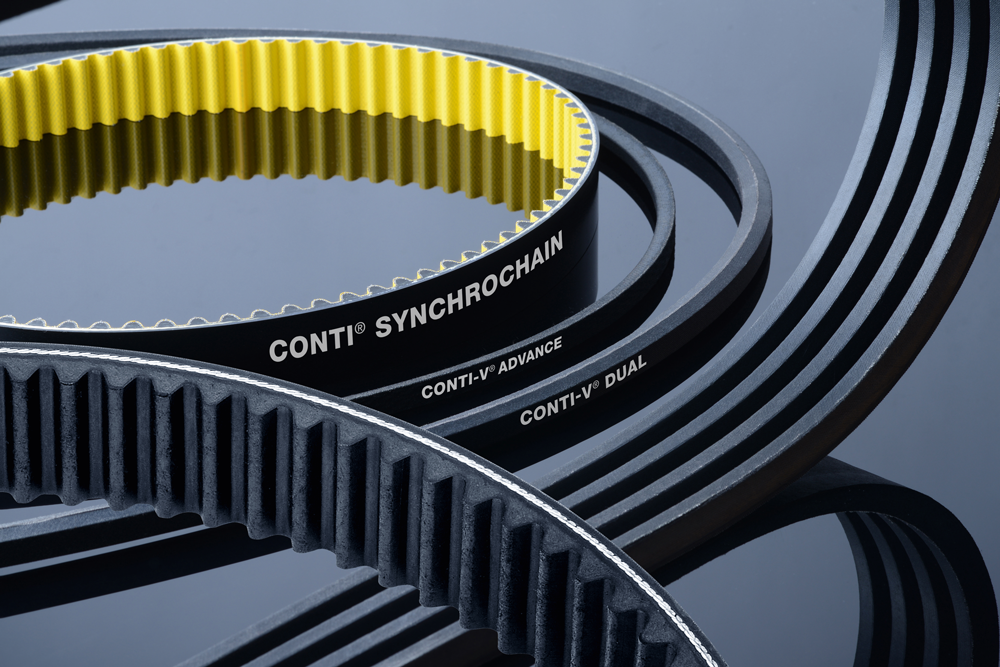

Since then, Continental has been continuously developing its sophisticated range of belts in co-operation with its customers, today, producing solutions that provide drive systems for almost every industry. This means, that they can offer their entire range from a single source. That’s more than 20,000 different dimensions and designs – from classic V-belts to banded V-belts, variable speed belts, poly V-belts, flat belts, innovative timing belts made of rubber or polyurethane.

Continental‘s vast experience is reflected not only in material expertise and sophisticated design, but also in outstanding service. In partnership with its customers, Continental has the capabilities to find the right belt solution for the specific application, develop tailor-made solutions for individual requirements, and provide technical support onsite.

And, as a development and service partner for OEMs and their equipment, as well as a hand in the replacement business, their focus remains on Total Cost of Ownership.

Monitoring your total costs

There’s one thing to always bear in mind. It’s worth looking at the performance of your belts, not just the price. It’s not just the longer service of higher quality solutions that pays off.

Using high-performance belts can significantly reduce the system’s overall width. The multiple advantages are as clear as day. So, as a result, the drive is lighter, quieter, less expensive, and more efficient in all areas. This, of course, saves you money.

Opt for carbon for longer service life

The Conti Synchochain Carbon timing belt is an excellent example of a heavy-duty belt.

The carbon structure for the tensile member makes possible higher power transmission, longer running times, and 50 percent less elongation than an aramid tension member. This means that it’s extremely wear- and abrasion-resistant, and maintenance-free.

In fact, the service life is up to 100 percent longer compared to other heavy-duty timing belts available on the market.

The cord fabric’s high rigidity also prevents unwanted pre-tensioning losses over the entire service life, increasing the efficiency of the drive and reducing operating costs.

Thanks to its extraordinary power-to-size ratio, drives can also be built up to 80 percent narrower with the Conti Synchrochain Carbon, meaning that your Total Cost of Ownership always sits on the positive side.

Narrow section equals compact drive

The use of narrow section V-belts offers economical advantages compared withconventional V-belts. When designing a belt drive, multiple belt types are often possible, therefore selecting the right V-belt is crucial if you are looking to achieve optimum power transmission, service life, and reduced maintenance costs.

In an attempt to achieve the above, the use of raw-edge narrow V-belts, such as the Conti-V FO Pioneer, should always be considered first. In short, these belts have the highest power transmission, the best efficiency, and the longest service life. They can be used with smaller pulley diameters, high belt speeds, and high transmission, and can accordingly be designed more compact and with lower overall costs.

Correct mounting and maintenance essential

We all know that drive belts are a reliable and powerful means of power transmission. But that’s because they are so undemanding that they are often neglected and don’t even get the little attention they require.

But the failure statistics speak for themselves: Incorrect maintenance, defective mounting and incorrect design are behind three- quarters of belt failures. To counteract this damning statistic, correct mounting and maintenance of your belt drives should be a prerequisite if you strive for trouble-free and long-standing functions.

With the capacity to provide expert advice, training and learning platforms, Continental service tools prevent failures. These devices are ready for immediate use and assist you in reducing maintenance work to a minimum.

The ‘right’ tool

Even the best belt is only as good as the conditions it’s set in. Incorrectly installed belts run rougher, causing vibrations in the machine, and are generally much louder, therefore correct belt tensioning and alignment of belt pulleys is essential. In short, paying close attention to these two parameters will mean that early and cost- intensive failures can be avoided.

Optical and acoustic maintenance is the first and most simple step, with tools from Continental further assisting in correcting the errors during the next steps. For example, the VSM Mini Tension Gauge helps to set the correct installation tension, courtesy of the acceleration sensor that operates perfectly even in loud environments, while its compact design allows it to slip easily into any toolbox.

When it comes to alignment, the Conti Laser Aligner is suitable for controlling and aligning belt pulleys. This intuitive and highly accurate tool makes it possible to achieve maximum service life, for all types of belts, and is ready for immediate use. In addition, customers can also introduce Conti Professional Calculation Software, enabling customers to calculate their own belt drives.

For more information on Power Transmission solutions and to get in touch with one of our ERIKS Motor Specialists or Power Transmission Engineers, please contact your local ERIKS Service Centre, who will be happy to discuss your options.

#Continental #Contitech #ERIKS #LetsMakeIndustryWorkBetter #Motor #Motors #MotorLegislation #Legislation #Engineering